REVERSE OSMOSIS SYSTEM

Installation and Service Guide

Please read this manual carefully before attempting installation

Thank you for choosing SoftPro Water Systems.

You now own the finest water filter in America.

Your Reverse Osmosis (RO) System has been tested to ensure it will operate correctly. The following periodic maintenance is recommended so your system will provide years of trouble-free service:

Filter Replacement Schedule:

(depends on usage and water quality)

- Sediment and Carbon pre-filters and post-filters ... 12 months

- RO Membrane ... 12 months

- Alkalizing post-filter ... Typically 24 months

NOTICE: THIS PRODUCT HAS LIMITED WARRANTY. BY INSTALLING AND OR USING THIS PRODUCT, YOU WAIVE CERTAIN LEGAL RIGHTS INCLUDING THE RIGHT TO SUE OR CLAIM COMPENSATION IN THE EVENT OF PROPERTY DAMAGE, INJURY, AND OR DEATH.

The following tools may be necessary, depending on each particular installation:

- Power drill with appropriate drill bit types (1/4” & 3/8” sizes)

- Phillips head screw driver

- 6” adjustable wrench

- Hammer & Center punch

- Plastic tubing cutter/ Scissors

- Additional plumbing connections depending on requirements. (not included)

- Optional ice maker fittings as required (tee, shut-off valve, not included)

The following components make up your reverse osmosis system:

Prefilter #1

(sediment filter) Melt down Polypropylene filter removes larger particles such as dirt, rust & sediment.

Prefilter #2 & #3

(if applicable) 10 Micron Carbon Block removes chlorine and chemical contaminants in the feed water and protects the RO membrane.

Reverse Osmosis Membrane

Thin Film Composite Membranes reduces dissolved minerals, metals, and salts. In this process, harmful compounds are separated by the membrane from the water, and the contaminants are flushed to the drain.

A coconut shell activated carbon postfilter is provided for a final polish and to remove tastes, odors and to provide great tasting water.

The RO module is the main component and holds the prefilters and membrane, and postfilter. A bracket is provided so they can be mounted under the sink or in a basement.

Storage tank

Holds RO purified water, and is ready to use.

Automatic shut-off valve

Closes when the storage tank is full and shuts off the water supply to conserve water. The valve activates when the tank pressure is 2/3 of the feed pressure.

The RO Faucet is used to dispense purified water when you want it.

Feed water saddle valve

Connects to the cold water line to supply water to the RO system.

Wastewater saddle valve

Connects to the drain to remove reject water from the RO system.

Tubing

Connects all RO components.

Quick-Connect Fittings

Are used for necessary tubing connections. These fittings connect by pushing the tube into the fitting past a slight resistance until the tube bottoms out in the fitting. Simply make a clean cut in your tubing and gently push in the tubing until it will not go any further.

To ensure that your tubing has made a snug fit, pull back gently on the tubing; it should catch. Always check for leaks to ensure a watertight connection.

⚠️

Your RO system may be installed under a sink or in a basement. Do not install unit where it would be exposed to freezing temperatures. Connecting to an icemaker or other remote location can also be considered if a connection can be made without using more than 12” of tubing, otherwise a delivery pump may be needed. Farther runs can be attempted and a pump can be added later only if needed

Guidelines for component placement are as follows:

Faucet

Faucet should be placed on, or near the sink where drinking/ cooking water is normally required. A 2” flat surface is required to mount faucet if an existing hole is not available. The thickness of the mounting surface should not exceed 1¼” or a faucet extension (not included) will be needed.

Storage Tank

Bladder Tank maybe placed where it is convenient, within ten feet of the faucet. Under the sink or in a nearby cabinet or in basement rafters are excellent choices. Full tanks can weigh more than thirty pounds; so make sure any shelving used is secure. Bladder tank can be placed on its side or upright.

RO Unit

RO Unit may be mounted on either side of the sink, in the back of a cabinet, or in the basement. Mounting the unit on the left or the right side of the cabinet under the sink provides for easier access to the unit for future maintenance.

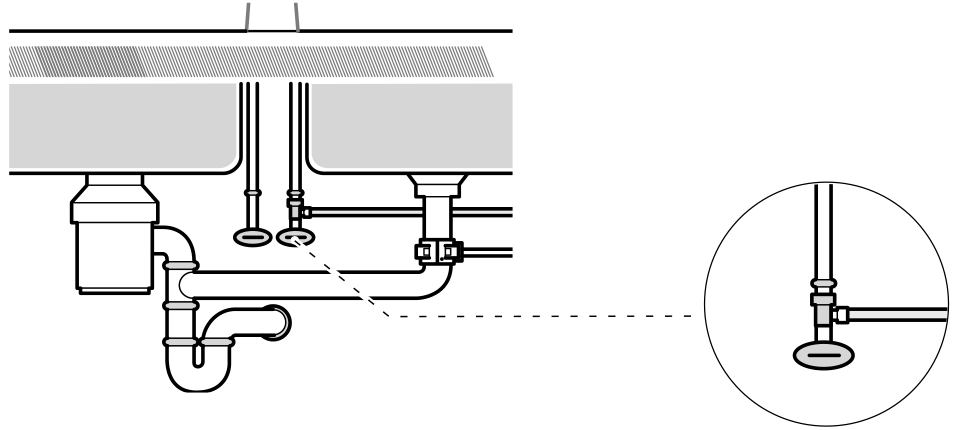

Drain Saddle

A Drain Saddle is used to make a waste water connection with your drain under the sink. This is designed to fit around a standard 1-1/2” OD drainpipe. The drain saddle valve should always be installed before (above) the p-trap and on the vertical or horizontal tailpiece.

Do not install the drain saddle near a garbage disposal to avoid clogging the drain line with debris.

Faucet Adaptor & Ball Valve Shut-of

A Faucet Adaptor and Ball Valve Shut-Off are used to supply feed water to the RO unit and provide an easy ability to shut off the water supply when servicing the unit. These are shown below

SYSTEM AND FAUCET DIAGRAM

BEFORE INSTALLATION

⚠️ ALL GOVERNMENT CODE AND REGULATIONS GOVERNING THE INSTALLATION OF THESE DEVICES MUS BE OBSERVED.

Water Pressure Requirements:

60+ PSI is preferred for optimal RO filtering operation. 40 PSI is the minimum.

Options to increase water pressure:

- For private well water sources: Adjust the pressure tank regulator, if applicable.

- Water Booster Pump: Installing a water booster pump may be an option to

increase the water pressure. The booster pump can be installed in before feeding untreated water into the RO system. (Not included.)

Water Booster Pump May Be Required:

A booster pump (not included) increases the water pressure after filtering through the RO system. It is commonly required to properly deliver RO water in some installation scenarios. Typical scenarios, includes:

- Feeding multiple treated RO water lines from the RO system, and/ or

- The RO water delivery distance is greater than 20 feet from the RO system

- Located in a basement, or the ice maker is located across the room.

- If RO water is feeding the ice maker, and the it is sputtering, then a booster pump may be needed to increase the water pressure

Installation Guide

1) Assemble the RO Filter System.

a. The RO filter system we come pre-assembled.

1. The advanced alkalizing filter or carbon block post-filter may need to be snapped into the top RO membrane filter.

(see exploded diagram p.14)

Please install now.

2) Mount the RO faucet.

a. Locate the RO Faucet location

(Under-sink cabinet or basement)

1. Requirements:

- Minimum of 2 inches of counter-top clearance for the RO faucet mounting hardware.

- Minimum of 2 inches of counter-top clearance for the RO faucet mounting hardware.

- Minimum of 2 inches of counter-top clearance for the RO faucet mounting hardware.

- Combined countertop/ sink is no thicker than 1.25” inches, or a faucet extension may be required (not included).

- Keep in mind though if you have a granite, quartz, or any kind of stone countertop that can crack or split, or if the countertop is over 1” thick, please consider hiring a professional drill the faucet hole.

- Check that the RO faucet can swivel freely and can empty into the sink.

- Long runs to feed an ice maker may require a delivery pump (not included).

2. Location Option: Alternatively to drilling a new RO faucet hole, you may opt to re-purpose another hole such as a sprayer or soap dispenser hole to install the new RO faucet.

b. Drill a new 1/2” hole for the RO faucet.

Caution: For granite, quartz, ceramic, and other

countertop materials that can crack, chip or scratch,

consulting or hiring a professional is recommended.

Use the appropriate drill bits.

(Below is only applicable for stainless steel sinks.)

- Mark the center with center punch for the 1/4” pilot hole.

- Drill the 1/4” pilot hole.

- Continue to enlarge hole to a 1/2” drill size

- Debur and clean up any sharp edges on the sink.

c. Install the RO faucet.

1. Assemble the RO faucet as shown

2. Insert the faucet assembly into the RO faucet hole from the top.

3. Attach the washers and nut from the bottom.

4. Attach the RO faucet tubing connector to the bottom of the threaded shank. Hand tighten and then use a wrench to tighten only another half of s turn.

Tip: It is best to have someone hold the faucet from above the sink to keep

it from moving out of place.

If this is not possible then tighten the hex nut

until it is just slightly less than completely tight. Then turn the faucet base

from above the sink, tightening it while orienting the faucet in the desired

location

3) Install the RO storage tank valve.

1) Wrap Teflon tape around the threads on top of the tank. i. Wrap Teflon tape clockwise around the thread 5-6 times.

2) Screw on a 1/4” tube valve. Hand tight only, do not overtighten.

i. Keep the storage tank valve in the off position.

3) Put the tank aside.

4) Tap into the water supply. Install the tubing water supply adapter/ shut-off valve.

a) Shut-off the main cold-water supply

b) Turn on the sink faucet cold water to drain the remaining water.

c) Disconnect the cold-water sink faucet supply hose from the supply shut-off valve/ angle stop valve.

(Use a towel to catch any remaining water in the hose.)

NOTE: If an ice maker line already exists, then please remove or close this existing line. Later, you can tee into the new RO faucet line to supply filtered RO water to your ice maker.

d) Screw the 1/4” tube valve adapter onto the supply valve.

- Hand tighten and then use a wrench to tighten only another half of a turn.

e) Screw on the sink faucet hose to this 1/4” tube adapter valve.

- Hand tighten and then use a wrench to tighten only another half of a turn.

Flexible Riser Hose

Most riser hoses that are used today are made of flexible material, either braided

stainless steel, braided plastic or gray 3/8” plastic tubing.

These flexible tubes

are the easiest to use with the angle stop valve because the 2” of additional

space needed for the faucet adaptor can be easily accommodated by flexing this

kind of riser. A shorter riser hose will not be needed.

Copper Riser Tube

If your riser tube is made of copper you will need to either make a bend in the copper to allow for the 2” of space needed for the John Guest angle stop valve. If the copper tube is 3/8”, bending it can be done easily by hand.

The angle stop valve works with 3/8” shut-off valves and riser tubes. In some

cases, older plumbing may use a larger size shut-off and riser tube.

In this case,

it would be necessary to either replace the old valve and riser tube with new 3/8”

parts, or use an alternative connection to draw the water supply to the reverse

osmosis system.

Alternatives include self piercing valves, T-fittings, and faucet

adaptors that connect between the faucet and the top of the riser tube.

Please consult your distributor or an installation professional for additional assistance

5) Install the drain saddle.

a. Locate and mark the drain saddle location. - Drain saddle must be located above the P-trap.

(Note: corroded pipes should first be replaced.)

b. Center and stick the black rubber gasket pad on the inside of the drain saddle hole

c. Position the drain saddle hole to the new drainpipe hole and attach the drain saddle clamp unto the drainpipe

d. Drill a pilot hole into the tube opening of the drain saddle with 1/4” drill bit. Then enlarge the hole with a 3/8” bit.

Note: Only drill one side of the drainpipe. Do not drill through the other side of the drainpipe.

6) Mount the RO filter assembly to the wall.

a) Place the two mounting panhead screws at least 15 inches above the floor and 7” apart from each other.

- Leave some space between the wall and screw head

- This is where the filter mount will sit.

b) Sit the RO filter assembly mount onto the two mounting screws

7) Connect the tubing.

(Refer to the quick-connect tube tutorial)

Note:

- The 3/8” tubing is slightly larger than the 1/4” tubing and will only be used for this application

- Cut the appropriate tubing to length as needed while leaving enough slack for any future maintenance.

- Color of tubing may vary.

a) Attach the black 1/4” drain tube from the drain saddle to the filter system

This is a gravity fed drain tubing line. This tubing should be placed in a direct path to the drainpipe without any loops, kinks or sharp bends. Cut this tubing as appropriate.

1. Start by loosening the compression nut on the drain saddle.

2. Insert the 1/4” tubing into this compression nut until it full seats

3. Hand-tighten the nut, and then use a wrench to tighten another 1-2 turns

b) Attach the yellow 1/4” tubing from the new 1/4” tubing supply valve to the inlet sediment filter

c) Attach the red 3/8” tubing from the alkalizing or carbon post-filter to the storage tank valve

d) Attach the blue 3/8” tubing from the RO faucet to the alkalizing or carbon post-filter filter

Note: If an ice maker line is to be supplied with this filtered RO water, Tee into the RO supply line. (These parts are not included.)

1. Cut this RO water supply line and insert 3/8” tubing tee

2. On the ice maker line side, add a 3/8” tubing valve

- Keep this valve in the closed position until the RO filter system is cleaned and ready for service

3. Then connect this RO water supply line to the ice maker line.

QUICK-CONNECT CONNECTION

Insert tube

Fitting grips before it seals. Ensure tube is pushed into the tube stop.

Push up to tube stop

Push the tube into the fitting, to the tube stop. The collet (gripper) has stainless steel teeth which hold the tube firmly in position while the O-ring provides a permanent leak-proof seal.

Pull to check secure

Fitting grips before it seals. Ensure tube is pushed into the tube sto

Disconnecting

Push the tube into the fitting, to the tube stop. The collet (gripper) has stainless steel teeth which hold the tube firmly in position while the O-ring provides a permanent leak-proof seal.

8) Start-up your new water RO filtration system.

a. Shut-off the sink faucet

b. Turn-on the RO faucet.

c. Slowly turn-on the water supply valve.

d. Slowly turn-on the ¼” tubing supply valve adapter. Water will start running through the RO filter system and out of the RO faucet

e. Flush out the RO system by keeping the RO faucet.on for 3-4 minutes.

- Air and black carbon particles are common to flush out. This will stop once the system is fully flushed.

f. Check for leaks at this time and adjust as needed.

g. Shut-off the RO faucet after flushing the system.

h. Turn-on the storage tank valve

- Allow the system to produce RO filtered water and fill the storage tank (about 2hours)

Note: If an ice maker line was opted, please turn on the ice maker

valve to supply the RO water to it.

Your RO filter system is now supplying the ice maker.

--- Your RO filtration system is completed ---

Ice Maker Hookup

Optional and requires a T fitting and additional shut-off valve. Not supplied with RO unit.

The RO unit can be connected to any standard refrigerator ice maker or ice maker/water dispenser.

⚠️ Do not connect to a commercial type bar ice maker.

⚠️ Hooking up to existing copper tubing is not recommended due to possible corrosion.

To complete this operation, connect a T with a shut off valve into the faucet tubing

and route tubing to the refrigerator.

Turn off the ice maker inside freezer prior to turning off the existing tap water supply line to the ice maker.

Turn on the icemaker after the RO system

has been drained several times and the tank has a full supply of water.

Note: These additional parts are not included. The water flow rates with an RO filter system may decrease to an ice maker. The refrigerator may have the option to re-calibrate flow rate of the new incoming RO water feed.

Replacing Filters & Sanitizing The System

Each year the filters in the system should be replaced. Usually the membrane can be replaced every other year, but the prefilters and post-filter should be changed annually and in some cases more often.

Filter Replacemen

1. Turn off valve on RO bladder tank.

2. Turn off feed water pressure.

3. Open RO faucet to relief pressure.

4. Using the supplied housing wrench remove the filter housing.

5. Discard old filters.

6. Clean filter housings with a cleaning brush

7. Follow sanitizing steps in “Sanitizing the System” section

8. Install new filters in system

9. Remove and replace GAC Post filter. Remove fittings from old post filter, re-apply Teflon tape and install fittings in new post filter.

10. Turn on feed pressure.

11. Open tank valve.

12. Allow water in tank to flush out post filter and run to drain until empty. Run 2 more complete batches to drain before using water

Membrane Replacement

1. Remove the supply tube from the end of the membrane housing that has only 1 tube

2. Unthread the cap from the membrane housing

3. Remove membrane using a pair of pliers

4. Clean membrane housing with a brush.

Note: When installing a new membrane be sure to push the membrane into the housing as far as it will go. Each time the filters are replaced it is recommended that the system be sanitized

Sanitizing the System

After all filters are removed from the system, housings have been cleaned, tank is empty, and faucet is open.

1. Add 1 gallon of water to a clean bucket.

2. Add 1 teaspoon of unscented household bleach.

3. Add 1 cup of this solution to each filter housing.

4. Tighten filter housings with solution on RO assembly.

5. Open tank valve and feed pressure valve.

6. Clean filter housings with a cleaning brush.

7. Allow water to fill the RO housing assembly until water comes out of faucet.

8. Close the faucet.

9. Allow water to run for 5 minutes.

10. Shut-off feed pressure.

11. Allow solution to stand for 30 minutes.

12. Open faucet and allow system to drain.

13. Remove water from housings before installing new filters and membrane.

14. Install new filters, tighten housings, and reconnect all tubing connections.

15. Open feed pressure valve and check for leaks.

16. Allow the system to make a full tank of water.

17. Run 2 cycles to drain to rinse out sanitizing solution before using water.

RO Systems are highly sensitive to pressure and

temperature. RO Membranes always perform better under

higher pressures. They produce more water, faster, and

of better quality with high pressure. The vast majority of

problems with RO Systems are a result of low pressure.

The effects of low pressure include water constantly

running to the drain, slow water production and low water

volume available in storage tank. In these cases where low

pressure exists, a booster pump will be required

On the following page is a table showing RO Membrane

performance over a range of temperatures and pressures.

Membranes are tested at 65 psi of pressure and

temperature of 77 degrees.

For each incremental change

in either variable, membrane performance changes

accordingly. Higher pressures increase production and vice

versa.

EXPLODED DIAGRAM

System components

1. Cold Water Line

2. Angle Stop Valve

3. Cold Water Shut-off Valve

4. Melt Down Sediment Pre Filter

5. Carbon Block Pre Filter

6. Nipple

7. Mounting Bracket

8. Single Clip

9. Automatic Shut-off Valve

10. RO Membrane Housing

11. Check Valve

12. Tank Valve

14. Double Clip

15. Inline Granular Carbon Post Filter

16. Drain Flow Restrictor

17. Quick-Connect Faucet Connector

19. 1 1/2” Drain Pipe

18. Reverse Osmosis Water Faucet

20. Drain Clamp

- Locking clips are used on fittings where the tubing has a bend near the fitting.

- Units come with plugs in the inlet, outlet and open end of T on the post-filter to create an air tight seal. Remove these plugs to perform the installation.

![Aldex Premium 10% Cross Link Resin for Water Softener [High Capacity]-SoftPro® Water Systems](http://www.softprowatersystems.com/cdn/shop/files/Aldex_10_Cross_Link_Resin_Premium_High_Capacity_for_Water_Softener_600x.jpg?v=1735853599)